- Home Page

- Company Profile

- Our Products

- Our Infrastructure

- Contact Us

Concrete Grade Silica Fumes

Price 12 INR/ Kilograms

MOQ : 10000 Kilograms, Kilograms

Concrete Grade Silica Fumes Specification

- Application

- Construction

- Product Type

- Refractories

- Types of Refractories

- Acid Refractory

- Shape

- Powder

- Strength

- 45 to 100

- Chemical Composition

- Sio2

- Color

- Grey

Concrete Grade Silica Fumes Trade Information

- Minimum Order Quantity

- 10000 Kilograms, Kilograms

- FOB Port

- Mundra Port

- Payment Terms

- Letter of Credit (L/C), Letter of Credit at Sight (Sight L/C), Telegraphic Transfer (T/T), Cash in Advance (CID), Cash Advance (CA)

- Supply Ability

- 1000 Kilograms, Kilograms Per Month

- Delivery Time

- 1 Week

- Sample Available

- Yes

- Sample Policy

- Free samples are available

- Packaging Details

- hdpe bags or jumbo bags

- Main Export Market(s)

- Middle East, Africa, Asia

- Main Domestic Market

- All India

- Certifications

- ISO 9001 - 2015

About Concrete Grade Silica Fumes

Silica Fumes is used for making High Strength Concrete.With the addition of Adinath Micro Silica weight density of concrete reduces by 75-80%.Thus, Adinath Micro Silica with cement concrete can be effectively used as light weight concrete for the construction of structures where the weight of structure is of supreme importance. The use of Adinath Micro Silica in concrete leads to around 8-12% saving in material cost. So, the addition of Adinath Micro Silica in concrete helps in making an economical concrete.High SiO2 Concrete Grade Silica Fume

Our silica fume powder is engineered with a high silicon dioxide (SiO2) composition, significantly increasing the strength and density of concrete. Its utilization in the construction industry leads to high-performance structures with improved resistance to chemical attack and reduced permeability, ensuring long-lasting durability under harsh conditions.

Acid Refractory Performance

Designated as an acid refractory, this silica fume performs exceptionally well in applications that require resistance to high temperatures and chemical erosion. Its properties enable its use in specialized bricks and linings for furnaces, reactors, and other high-heat environments commonly found in industrial processes.

FAQs of Concrete Grade Silica Fumes:

Q: How is concrete grade silica fume applied in construction projects?

A: Concrete grade silica fume is usually added to concrete mixtures as an admixture to enhance its compressive strength, durability, and resistance to chemicals. It is thoroughly mixed with cement, aggregates, and water to form high-performance concrete used in bridges, tunnels, and industrial flooring.Q: What are the benefits of using silica fume with high SiO2 content?

A: Silica fume with high SiO2 content significantly enhances the density, strength, and durability of concrete. It reduces permeability, improves resistance to chemical and thermal attacks, and enables the production of acid refractory materials required for demanding industrial environments.Q: When should silica fume be incorporated into concrete mixes?

A: Silica fume is ideal for use when constructing structures that require increased strength, reduced permeability, and enhanced durability. It is particularly beneficial in marine, industrial, or infrastructure projects exposed to aggressive environments.Q: Where can concrete grade silica fume be sourced in India?

A: Concrete grade silica fume can be sourced from reputable exporters, manufacturers, and suppliers across India who specialize in high-quality construction-grade materials, ensuring consistent chemical composition and performance.Q: What is the process of manufacturing high-purity silica fume?

A: High-purity silica fume is produced as a by-product during the manufacturing of silicon or ferrosilicon alloys. The fume is collected, processed to remove impurities, and then packaged as a fine, grey powder suitable for use in construction and refractory applications.Q: How is silica fume beneficial in creating acid refractory materials?

A: Due to its high SiO2 content and acid-resistant properties, silica fume serves as an essential ingredient in producing acid refractory bricks and concrete. These materials are used in lining furnaces and vessels exposed to corrosive environments and high temperatures.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Minerals Category

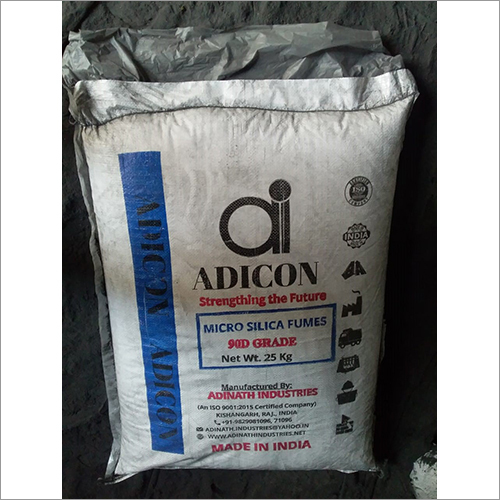

Micro Silica Fumes

Price 12.00 INR / Kilograms

Minimum Order Quantity : 400 Kilograms, Kilograms

Types of Refractories : Acid Refractory

Shape : Powder

Product Type : Refractories

Application : construction

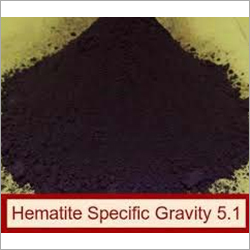

Hematite Powder

Price 20000.0 INR / Metric Ton

Minimum Order Quantity : 100

Types of Refractories : Acid Refractory

Shape : Powder

Product Type : Minerals

Application : Oil Drilling, refinery

Send Inquiry

Send Inquiry

Call Me Free

Call Me Free