- Home Page

- Company Profile

- Our Products

- Our Infrastructure

- Contact Us

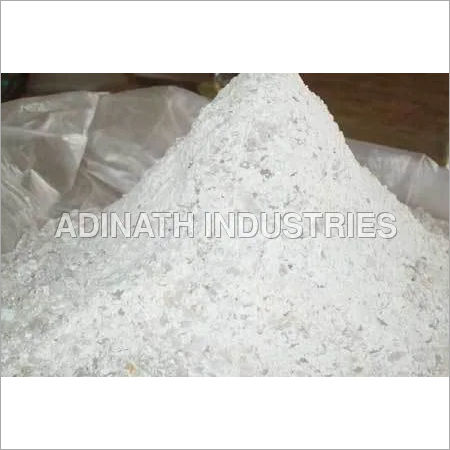

Acidic Ramming Mass

Price 3200 INR/ Metric Ton

MOQ : 20 Metric Tons

Acidic Ramming Mass Specification

- Color

- White

- Material

- Magnesite

- Shape

- Powder

- Fe2O3 (%)

- SiO2 98-99%

- Refractoriness

- Acidic Ramming Mass

Acidic Ramming Mass Trade Information

- Minimum Order Quantity

- 20 Metric Tons

- Supply Ability

- 1000 Metric Tons Per Week

- Delivery Time

- 2 Week

About Acidic Ramming Mass

We are the foremost manufacturer, exporter and supplier of Acidic Ramming Mass. This product is generally used For Patching in Steel Furnaces. The quality of acidic ramming mass is processed using related to the heating action of the furnaces. This chemical is strictly processed under the strict supervision of qualified & experienced professionals using 30-80 or hammer mill. Further, this Acidic Ramming Mass can be availed from us at industry prices.

Features:

- Better quality of lining results

- Smooth working of furnaces

- Optimum output

- Better metallurgical control

Chemical Specifications:

| SiO2 | 98 to 99.9 % |

| Al2O3 | TRACE |

| Fe2O3 | 00.085% |

| CaO | TRACE |

| MgO | NIL |

| LOl | 00.425% |

| Na2O | 00.120% |

| K2O | 00.270% |

Major markets : India, South Africa, Saudi Arabia, UAE, Middle East, Central Asia

Superior Composition for High Performance

Our Acidic Ramming Mass is formulated with over 98% SiO2 and pure magnesite, resulting in an exceptionally stable and pure white powder. This composition ensures optimal refractoriness, making it highly suitable for induction furnace linings, reducing contamination and improving furnace efficiency.

Applications in Metallurgical Processes

Ideal for lining induction furnaces, Acidic Ramming Mass offers thermal stability and resistance to corrosion. It is essential in steel and foundry industries, helping enhance the quality of the final metal by preventing reactions between the furnace lining and molten metal.

FAQs of Acidic Ramming Mass:

Q: How is Acidic Ramming Mass manufactured?

A: Acidic Ramming Mass is produced by selecting high-grade magnesite and silica. These raw materials are crushed, purified, and ground into a fine powder, typically achieving 98-99% SiO2 content. The mixture is then sieved to ensure uniform particle size for optimal lining application.Q: What are the main uses of Acidic Ramming Mass?

A: This product is primarily used for lining induction furnaces in steel and foundry applications. Its high refractoriness and resistance to chemical attack make it an ideal material for containing molten metal and extending furnace life.Q: When should Acidic Ramming Mass be applied in furnace operations?

A: It should be applied during the initial lining of a new furnace or when relining is required due to wear and tear. Regular maintenance with Acidic Ramming Mass ensures consistent furnace performance and helps prevent furnace breakdowns.Q: Where is your Acidic Ramming Mass exported and supplied from?

A: We manufacture and supply Acidic Ramming Mass from India, exporting to various countries across the globe. Our network ensures timely delivery to different industrial regions.Q: What is the process of applying Acidic Ramming Mass in furnaces?

A: The powder is carefully raked and rammed by hand or vibration onto the furnaces inner walls. It is then dried and sintered gradually, creating a seamless, durable lining that resists heat and corrosive attack during metal melting.Q: What are the benefits of using Acidic Ramming Mass with a high SiO2 content?

A: A high SiO2 content enhances the products thermal stability, prolongs the life of the lining, and minimizes iron pickup. This leads to better energy efficiency, lower maintenance costs, and improved purity of the finished metal.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Ramming Mass Category

Ramming Mass

Price 3200.0 INR / Metric Ton

Minimum Order Quantity : 20

Al2O3 Content (%) : 0.02

Fe2O3 (%) : SiO2 9899%

MgO % : 0.01

Color : White

Silica Ramming Mass

Price 3200.00 INR / Metric Ton

Minimum Order Quantity : 20

Al2O3 Content (%) : 0.02

Fe2O3 (%) : 0.03

MgO % : 0.01

Color : White

Send Inquiry

Send Inquiry