- Home Page

- Company Profile

- Our Products

- Our Infrastructure

- Contact Us

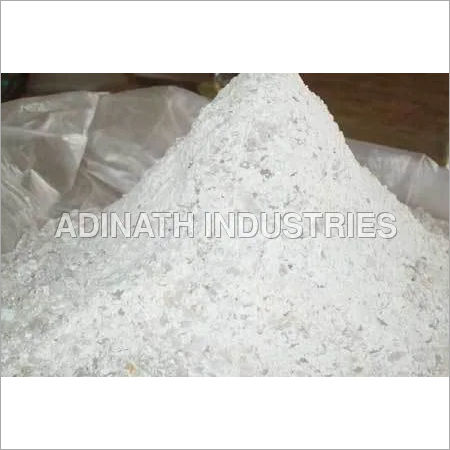

Ramming Mass

Price 3200.0 INR/ Metric Ton

Ramming Mass Specification

- Material

- Quartz

- CaO Content (%)

- 0.01

- SiO2 Content (%)

- 98

- Shape

- Granule

- Fe2O3 (%)

- SiO2 98-99%

- MgO %

- 0.01

- Density

- 2.4 Kilogram per cubic meter (kg/m3)

- Al2O3 Content (%)

- 0.02

- Color

- White

Ramming Mass Trade Information

- Minimum Order Quantity

- 20 Metric Ton

- FOB Port

- Mundra Port

- Payment Terms

- Cash in Advance (CID), Letter of Credit at Sight (Sight L/C), Telegraphic Transfer (T/T), Letter of Credit (L/C)

- Supply Ability

- 1000 Per Month

- Delivery Time

- 1 Week

- Sample Available

- Yes

- Sample Policy

- Free samples are available

- Packaging Details

- hdpe bags or Jumbo Bags

- Main Export Market(s)

- Asia, Middle East, Africa

- Main Domestic Market

- All India

- Certifications

- ISO 9001 - 2015

About Ramming Mass

With the support of experienced team of professionals, we have been able to manufacture, export and supply premium quality Ramming Mass. Offered mineral is widely used in patching in steel furnaces to raise the performance and for self-balancing metallurgical control. Our Ramming Mass is processed under the supervision of experienced professionals using 30 - 80 or hammer mill. It is extensively acclaimed for better thermal stability and maximum efficiency.

Features:

-

Humidity resistance

-

Better thermal stability

-

Maximum purity

Specification of Ramming Mass after Laboratory Analysis:

SiO2: above 99%

Al2O3: TRACE

Fe2O3: 0.025%

CaO: TRACE

MgO: NIL

LOI: 0.425%

Na2O: 0.120%

K2O: 0.270%

We have 3 qualities of Ramming mass:

1. Snow White (Finest)

2. Super Semi

3. Semi

Unmatched Purity and Performance

Produced from high-grade quartz, our Ramming Mass boasts SiO2 content between 98% and 99%, ensuring excellent refractoriness and minimal reaction with molten metal. The granule shape ensures quick and even application, while its white color signals superior quality. Low content of CaO, Al2O3, and MgO results in minimal contamination, making it indispensable for high-efficiency furnace operations.

Reliable Exporter and Manufacturer from India

Based in India, we provide global supply solutions tailored for manufacturers, foundries, and industrial users. Our state-of-the-art processing and quality control measures ensure consistent material standards. As both exporter and supplier, we cater to diverse business volumes with reliability and prompt delivery.

FAQs of Ramming Mass:

Q: How is Ramming Mass used in induction furnace linings?

A: Ramming Mass is applied as a refractory lining in induction furnaces. It is evenly rammed between the coil and the crucible wall to form a robust, heat-resistant barrier that prolongs furnace life and enhances performance.Q: What makes your Ramming Mass suitable for industrial applications?

A: Our Ramming Mass, made primarily from high-purity quartz (98-99% SiO2), offers high thermal stability, low impurity levels, and dense packing. These characteristics make it ideal for steel, foundry, and non-ferrous metal melting industries.Q: When should Ramming Mass be replaced in a furnace?

A: Ramming Mass should be replaced when signs of wear, thinning, or cracking appear in the lining, often after several melting cycles, to maintain furnace safety and efficiency. The replacement interval varies based on operational intensity and maintenance practices.Q: Where are your Ramming Mass products manufactured and supplied from?

A: Our Ramming Mass is manufactured in India, where we maintain stringent quality controls. We supply and export to industries across domestic and international markets, ensuring timely and reliable delivery.Q: What is the process for installing Ramming Mass in a furnace?

A: The process involves first cleaning the furnace shell, then gradually layering and ramming the mass to form a compact, seamless lining. Proper drying and sintering are crucial before commencing furnace operations to achieve optimal lining strength.Q: What are the benefits of using high-purity Ramming Mass?

A: High-purity Ramming Mass minimizes chemical reactions with molten metal, improves furnace lining life, and supports consistent melting performance. Its superior properties also reduce downtime and maintenance costs for industrial operations.Q: How does the low content of CaO, Al2O3, and MgO affect the performance of Ramming Mass?

A: The very low levels of CaO, Al2O3, and MgO in our Ramming Mass ensure negligible contamination and reactivity within the furnace, thus optimizing process integrity, product quality, and lining durability.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Ramming Mass Category

Silica Ramming Mass

Price 3200.00 INR / Metric Ton

Minimum Order Quantity : 20

Color : White

Shape : Granule

Fe2O3 (%) : 0.03

Material : Quartz

Acidic Ramming Mass

Price 3200 INR / Metric Ton

Minimum Order Quantity : 20 Metric Tons

Color : White

Shape : Powder

Fe2O3 (%) : SiO2 9899%

Material : Magnesite

Send Inquiry

Send Inquiry

Call Me Free

Call Me Free