- Home Page

- Company Profile

- Our Products

- Our Infrastructure

- Contact Us

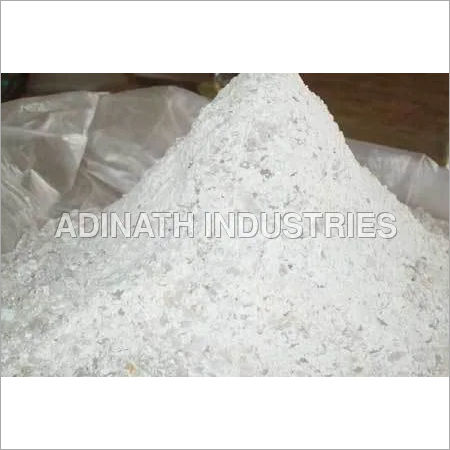

Silica Ramming Mass

Price 3200.00 INR/ Metric Ton

Silica Ramming Mass Specification

- Al2O3 Content (%)

- 0.02

- SiO2 Content (%)

- 98

- Fe2O3 (%)

- 0.03

- Shape

- Granule

- Material

- Quartz

- MgO %

- 0.01

- Color

- White

- CaO Content (%)

- 0.01

Silica Ramming Mass Trade Information

- Minimum Order Quantity

- 20 Metric Ton

- FOB Port

- Mundra Port

- Payment Terms

- Letter of Credit (L/C), Letter of Credit at Sight (Sight L/C), Telegraphic Transfer (T/T), Cash in Advance (CID)

- Supply Ability

- 2000 Per Month

- Delivery Time

- 1 Week

- Sample Available

- Yes

- Sample Policy

- Free samples are available

- Packaging Details

- hdpe bags of 50 kg or Jumbo Bags of 1000 kg

- Main Export Market(s)

- Middle East, Asia, Africa

- Main Domestic Market

- All India

- Certifications

- ISO 9001 - 2015

About Silica Ramming Mass

Silica Ramming Mass offered by our company, is available in its powder and Granules form. Its maximum granulation class is 6mm and true porosity is less than 13.5 %. B. It is produced by following automatic or manual ramming technique. Later, the rammed substance is heat treated by hardening at high temperature. Silica Ramming Mass is required during melting of cast iron alloy, high grade steel, copper alloy, brass, alloy steel and carbon steel. This product is very easy to use and simple to maintain and provide maximum shelf life while using.

Superior Purity and Performance

Our Silica Ramming Mass stands out due to its remarkable purity, with 98% SiO2 content and very low levels of iron, alumina, lime, and magnesia. This composition ensures minimal slag reaction and excellent heat resistance, making it a preferred choice for induction furnace linings. The granulated structure delivers consistent packing and robust furnace durability, maximizing your process efficiency.

Versatile Industrial Applications

This grade of Silica Ramming Mass is ideal for lining induction furnaces used in the melting of steel and various alloys. Its high refractoriness and chemical stability reduce furnace wear and tear, providing extended furnace life and minimizing downtime. Our products are trusted by industries across India and exported worldwide for their consistent quality and reliability.

FAQs of Silica Ramming Mass:

Q: How is Silica Ramming Mass used in the steel industry?

A: Silica Ramming Mass is mainly used for lining induction furnaces in the steel industry. Its high silica content and purity provide exceptional thermal insulation, supporting efficient steel melting and reducing slag formation.Q: What makes your Silica Ramming Mass stand out in terms of composition?

A: Our product contains 98% SiO2 with extremely low impurities, including 0.03% Fe2O3, 0.02% Al2O3, 0.01% CaO, and 0.01% MgO. This high purity promotes superior refractoriness and stability during high-temperature furnace operations.Q: When should Silica Ramming Mass be replaced in a furnace lining?

A: It is advisable to replace Silica Ramming Mass when you notice increased heat loss, frequent lining cracks, or reduced furnace performance. Regular inspections help determine the optimal replacement schedule, depending on melting cycles and usage intensity.Q: Where do you supply and export Silica Ramming Mass from?

A: We are based in India and supply Silica Ramming Mass to both domestic markets and international clients. Our extensive distribution network ensures timely exports and delivery to global foundries and steel plants.Q: What is the process for applying Silica Ramming Mass in furnaces?

A: The process involves evenly ramming the granulated mass into the furnace lining, followed by controlled heating to sinter the material. This creates a dense, monolithic structure that withstands high temperatures and thermal cycling.Q: What are the benefits of using high-purity Silica Ramming Mass?

A: Utilizing high-purity Silica Ramming Mass enhances furnace lining life, improves thermal efficiency, and minimizes unwanted chemical reactions. This translates to reduced downtime, cost savings, and consistent production quality for your operation.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Ramming Mass Category

Ramming Mass

Price 3200.0 INR / Metric Ton

Minimum Order Quantity : 20

Fe2O3 (%) : SiO2 9899%

Shape : Granule

Material : Quartz

Color : White

Acidic Ramming Mass

Price 3200 INR / Metric Ton

Minimum Order Quantity : 20 Metric Tons

Fe2O3 (%) : SiO2 9899%

Shape : Powder

Material : Magnesite

Color : White

Send Inquiry

Send Inquiry